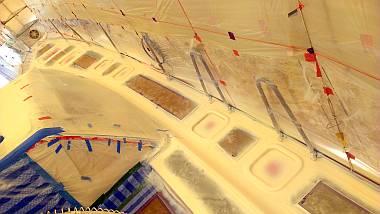

Lee and Mike spraying gelcoat on the targa-bar

Weekly Logs 2013

These are the weekly summaries of the work that was completed on Ocelot, in chronological order.

Newest entries are at the bottom so they can be read chronologically.

This page was getting too big, so we split it into 2012

and 2013.

| Month 1: | Week 1 | Week 2 | Week 3 | Week 4 | Oct 24 - | Nov 20, 2011 |

| Month 2: | Week 13 | Week 14 | Week 15 | Week 16 | Jan 16 - | Feb 12, 2012 |

| Month 3: | Week 17 | Week 18 | Week 19 | Week 20 | Feb 13 - | March 11, 2012 |

| Month 4: | Week 21 | Week 22 | Week 23 | Week 24 | March 12 - | April 8, 2012 |

| Month 5: | Week 25 | Week 26 | Week 27 | Week 28 | April 9 - | May 6, 2012 |

| Month 6: | Week 29 | Week 30 | Week 31 | Week 32 | May 7 - | May 31, 2012 |

| Month 7: | Week 40 | Week 41 | Week 42 | Week 43 | Aug 6 - | Sept 2, 2012 |

| Month 8: | Week 44 | Week 45 | Week 46 | Week 47 | Sept 3 - | Sept 30, 2012 |

| Month 9: | Week 48 | Week 49 | Week 50 | Week 51 | Oct 1 - | Oct 28, 2012 |

| Month 10: | Week 52 | Week 53 | Week 54 | Week 55 | Oct 29 - | Nov 25, 2012 |

| Month 11: | Week 56 | Week 57 | Week 58 | Week 59 | Nov 26 - | Dec 23, 2012 |

| Month 12: | Week 60 | Week 61 | Week 62 | Week 63 | Dec 24, 2012 - | Jan 20, 2013 |

| Month 13: | Week 64 | Week 65 | Week 66 | Week 67 | Jan 21 - | Feb 17, 2013 |

| Month 14: | Week 68 | Week 69 | Week 70 | Week 71 | Feb 18 - | March 17, 2013 |

| Month 15: | Week 72 | Week 73 | Week 74 | Week 75 | March 18 - | April 14, 2013 |

| Month 16: | Week 76 | Week 77 | Week 78 | Week 79 | April 15 - | May 12, 2013 |

| Month 17: | Week 80 | Week 81 | Week 82 | Week 83 | May 13 - | June 9, 2013 |

| Month 18: | Week 84 | Week 85 | Week 86 | Week 87 | June 10 - | July 7, 2013 |

| Month 19: | Week 88 | Week 89 | Week 90 | Week 91 | July 8 - | August 4, 2013 |

| Month 20: | Week 92 | Week 93 | Week 94 | Week 95 | August 5 - | Sept 1, 2013 |

| Month 21: | Week 96 | Week 97 | Week 98 | Week 99 | Sept 2 - | Sept 29, 2013 |

| Month 22: | Week 100 | Week 101 | Week 102 | Week 103 | Sept 30 - | Oct 27, 2013 |

| Month 23: | Week 104 | Week 105 | Week 106 | Week 107 | Oct 28 - | Nov 24, 2013 |

| Month 24: | Week 108 | Week 109 | Week 110 | Week 111 | Nov 25 - | Dec 22, 2013 |

| Month 25: | Week 112 | Week 113 | Week 114 | Week 115 | Dec 23, 2013 - | Jan 19, 2014 |

| Month 26: | Week 116 | Week 117 | Week 118 | Week 119 | Jan 20 - | Feb 16, 2014 |

| Month 27: | Week 120 | Week 121 | Week 122 | Feb 17 - | March 13, 2014 |

Lee and Mike spraying gelcoat on the targa-bar |

Week 61, December 31, 2012 - January 6, 2013:

A long week for us, as we worked all 7 days, including New Years. Our big accomplishment was

that the targa‑bar was stripped, prepped, masked, and sprayed with 2 coats of our "Ocelot White"

gelcoat by Mike and his AME team! The bimini was also prepped and 2 coats of gelcoat were shot

onto the underside. The top of the bimini got some gelcoat but a compressor malfunction

prevented finishing it. We only had a full set of workers on Thursday and Friday, and no

workers at all on Monday, Tuesday, or Sunday, which let us get 2 full coats of Nyalic on the

starboard side of the mast. Jon hauled out a huge tarp from the workshop, taped over its

holes, attached it to a long PVC pipe, and attached it along the starboard side of our tent so it

could be raised and lowered when necessary. Sue finger‑sanded the starboard deck to fair the

Thai gelcoat into the surrounding fiberglass. Houa made excellent progress in the heads,

ripping out the old rotten wood and building replacements in plastic‑board, which should get

installed next week. Two men from Luck Engineering arrived and finished tacking together the

railing for the starboard grab‑rail. Many of our removable hatches, louvers, etc were prepped

for final gelcoat while the AME team was spraying. Many of the vertical walls in the cockpit

were also sanded to prepare them for gelcoating, and the starboard sugar‑scoop got more filler to

improve its shape. Amanda spent several hours in her bunny‑suit, smoothing several patches of

fiberglass on Ocelot's hulls.

Mike and Deng spray final gelcoat layers on the bimini top |

Week 62, January 7 - January 13, 2013:

We noticed a wonderful change in the yard's attitude towards us this week - they actually seem to

like us. Mannop spent hours repairing our compressor (he's quite a mechanical magician) and

wouldn't accept any payment beyond parts. Hope the attitude lasts! Cris called our whole

team together for a meeting on Monday and translated everything so everyone's on the same page.

On the bimini, the men sanded and filled the top and the AME team came to finish spraying the

gutters and edges with gelcoat. Then our guys flipped it over and started wet‑sanding the

bottom, starting with 400 grit. Jack and Chai spent most of the week filling and sanding

smaller panels, hatches, and louvers in the newly expanded workshop, getting several ready for

spraying with gelcoat. Baw led a team filling and sanding the starboard sugar‑scoop and then

masking and spraying it with our ISO 2500 gelcoat. While he was spraying, he also sprayed

5 smaller hatches and covers that had been finished. The team from Luck Engineering finished

completely rebuilding both of our aft grab‑rails. Houa fitted the headliners and

2 plastic‑wood boards in each starboard head. He finished shaping the other 3 pieces for those

heads, but wants to paint them before installing them. Then he moved over to portside and

cleaned it to begin his work there. Sue and Amanda got TMT, who made our tent, to do all of

our headliners for us, a big job. Jon ran a test on the mast wiring conduit to determine the

force needed to force it up the mast - 286kg or 630 lbs. Several folks worked on the vertical

surfaces in the cockpit. They also finished most of the surround for the teak on the aft‑deck.

Middle of shoot - tape on near side has disappeared under gelcoat |

Week 63, January 14 - January 20, 2013:

Two big accomplishments this week: First, the underside of the bimini was

sanded to 2000 grit and polished, giving it a mirror-smooth reflective finish. Second, the

team prepared the cabin‑top and Mike sprayed all the areas outside of where the nonskid will go (the

"gutters") with gelcoat. This involved applying more durable masking to the windows and

filling all 100 mounting holes with epoxy, de‑coring the 22 holes that still needed it. The

team from Luck reworked the sugar‑scoop grab‑rails so they fit better, then took them off for final

polishing. Houa was pulled off the bathrooms and put onto making new plywood for the

headliners, to replace the water‑damaged ones. These were then epoxy coated. Lots of

work in the cockpit, and Jon remounted the starboard side aft cockpit door, as well as de‑coring the

area around the emergency steering bearings and the engine room hatch pulls. Several other

small epoxy jobs got done, including filling the holes in the starboard chain‑locker and in the

bottom of the life‑raft locker and where the backrest bolts to the aft cockpit seat. Jack

kept sanding the hatches and the cockpit seat, preparing them for gelcoating.

Mike spraying the foredeck inside a plastic tent of masking |

Week 64, January 21 - January 27, 2013:

The week started slowly but we ended up getting a lot done. Nut spend several days sanding the

underwater parts of the hulls (for which he received additional pay) removing the high spots so we

don't have to use as much filler to fill the gouges left by the grinders that took off the gelcoat.

K worked with Houa all week. They epoxied and sanded the headliner boards, then ripped out

some wet plywood in the portside cabins. Houa ripped out some rotten wood from the portside

heads and started making plastic‑wood replacements. Jon mounted and trimmed the portside aft

cockpit door and disassembled our feathering Kiwi prop, finding a bent spring inside. He

drilled a pair of drain‑holes in the new hatch gutters up forward, so we can mount PVC drain‑pipes

in them. He also found how to modify West System epoxy pumps so they'll work with our Epotek

epoxy! Baw's team worked on the foredeck, directly in front of the salon, and on the

targa‑bar, getting them ready to be sprayed with gelcoat. Sue and Amanda kept a close eye on

Baw's team, asking them to fill small defects they'd left behind. Friday and Saturday were

gelcoat spray days, as Mike and his team from AME sprayed the foredeck, the lower targa‑bar, several

hatches and louvers, and touched up 2 areas of the bimini. Our team did much of the masking,

and provided support when they weren't sanding the sprayed bits. Jack put tiny blobs of

gelcoat on the pinholes that formed in the gelcoat, saving us an additional sanding step.

Baw and Jack smoothing out filler under the sugar-scoop |

Week 65, January 28 - February 3, 2013:

The bad news this week is that we found that the epoxy filler on the outsides of our hulls and all

along the waterline is very soft and porous. Whether sun damaged or poorly mixed, it ALL has to come

off before we can start re‑contouring the hulls into nicely rounded shapes. Lots of

sanding that we weren't planning on. But the rudder bearing project looks a bit easier than

we'd thought, due to larger than expected rudder‑tubes. Baw and Nut made excellent progress

and finished preparing the port side‑deck for gelcoat, bagging it in plastic to preserve their work.

They also made good progress on the starboard deck, spreading filler on the hatch supports and

sanding it smooth. Houa and K worked on portside, creating plastic‑wood strips for the heads

and removing the rubber and plywood kick‑boards in the cabins, replacing them with formica. K

cut his thigh and needed 7 stitches, our worst accident to date. Jon found that West Epoxy

pumps can be modified for our Epotek epoxy, which led to us applying phenolic‑epoxy mud to the

starboard outside waterline. Two more applications were required before we had a nice, smooth

transition from topsides to hulls. Sue and Amanda worked on polishing the spars and cleaning

bits that need to be replaced. They also bought some epoxy paint from another cruiser, but it

turns out not to be appropriate for nautical work. Jon repaired R2D2, our shop vac, and

de‑cored our 2 water‑fill holes on deck. The starboard topsides were long‑boarded

(again) and some filler was spread into some low areas. And we spent a wonderfully glorious

Sunday out on the water, sailing to a neighboring island for some snorkeling.

Sanding off the remaining bad filler using big polishing motors |

Week 66, February 4 - February 10, 2013:

Lots more sanding and filling of the starboard topsides, but Baw mixed some of our new gelcoat

with some filler and it didn't harden, so it ALL had to come off - a huge job that saw the

yard contributing several power tools to us, all for free! Now we're back to filling and

fairing, making the topsides smooth and uniform. The guys typically do 2 filling/fairing

cycles a day. Jon epoxied in the gutter drains for the 2 new forward hatches and filled where

he'd de‑cored the water‑fill holes in the deck, and he also repaired a powerful grinder and a small

palm sander that we can now call our own. Baw shaped the starboard bow and then moved over to

port, sanding away the old filler first. We got the mast flipped over and Sue and Amanda

started polishing the port side. Our headliners came back from TMT and we talked with Doyle

(China) about making us new sails. Jon and Amanda started designing the pattern for the

cockpit teak, and also removed the starboard cap‑shroud chain‑plate. Our new worker,

Duk, started sanding off the old epoxy filler from portside. The inside waterline of starboard

hull was sanded clean and smeared with 2 layers of phenolic epoxy filler. Houa and K found

problems with the steps up to the portside bunks so they did a lot of repair work, as well as making

new bits of teak trim to go around the formica.

Spraying gelcoat on the starboard topsides - goodbye stripes |

Week 67, February 11 - February 17, 2013:

Both cap‑shroud chain‑plates were removed, along with their backing plates. The silicone

around them was cleaned up and then the 3 lower bolt‑holes in each were de‑cored before all of the

holes were filled with epoxy mud. Eight water/fuel vents were also de‑cored and filled with

epoxy mud. The starboard topsides were filled and faired smooth, then Jon and Amanda shot in a

gelcoat line (above the waterline but below the paint line) with the laser. Port topsides

needed more work as it had more bad filler to remove as well as the old whale damage repair, then

lots of filler was added to make it all smooth again. The waterlines on the inside of

starboard hull and the outside of port hull were sanded back and phenolic‑epoxy filler was screed on

and sanded smooth. Sue and Amanda put in a lot of time polishing the mast. Houa and K

worked on new bits of teak trim for the cabins, and new supports for the cabin floors. The

starboard topsides and the port side‑deck were completely masked off with heavy plastic so Mike and

the AME team could spray gelcoat on the starboard topsides on Thursday, and the port side‑deck on

Friday and Saturday. The guys started sanding the starboard topsides with 320 grit and soapy

water but after the gelcoat spraying was finished we put them to preparing port topsides for gelcoat.

Lining up the drill with strings to remove the lower rudder bearing |

Week 68, February 18 - February 24, 2013:

Most of the effort this week went into filling and long‑boarding the port topsides, getting them

ready to be sprayed with gelcoat. Sue, Baw and Nut put in a lot of time preparing the

starboard side‑deck for gelcoat, filling areas that need it and sanding out little pin‑holes.

Sue and Amanda also put in a lot of time on the mast, and fetching supplies for the men. The

vertical walls near the entryway and behind the aft cockpit seat were sealed with epoxy (to prevent

some blue paint from showing through) and then sanded rough to prepare them for gelcoat. Jon

repaired the charger for our battery‑drill and used a friend's sharpener to sharpen several of our

drill bits. Houa worked long hours alone, repairing much of the work that K had done badly

(K won't be back). Jon used string and a pair of tapered plugs to find the exact axis of our

rudder shafts, and super‑glued strings to the hull as guides for drilling out our old rudder

bearings. The yard provided a big drill and with Sue and Amanda acting as spotters, telling

Jon which way to point the drill, he drilled out both of our old rudder bearings and enough of our

rudder‑tubes to accept our new rudder bearings. This job was much tougher than expected, taking the

best part of 4 days. The port inside waterline was sanded and filled with phenolic‑epoxy, and

most of the guys started working on the bows, between the hulls, filling and fairing. Jon and

Amanda shot in the port gelcoat line with the laser, but Baw felt that port topsides needed more

work. It turned out that Mike was too ill to spray gelcoat so that was put off until next

week.

Rudder taped with the taped bearing sitting on the shaft |

Week 69, February 25 - March 3, 2013:

A good week as we made visible progress on several fronts despite Sue being out with a head cold for

much of the week and Amanda having to fly to Penang to renew her visa. The port topsides were

filled and faired smooth, masked, scaffolded, and shot with 30 kg (66 lbs) of gelcoat, which was

then completely wet‑sanded with 360 grit. It needs some touch‑up re‑spray but it's looking

nice. Mike also gelcoated the nonskid gutters on the starboard side‑deck while the guys

wet‑sanded the starboard topsides to 400. The bulk of the prep‑work happened between the hulls

and by the end of the week it had all been filled and faired smooth and the gelcoat line marked,

with new filler around the emergency hatches and the trampoline holders. The big news was that

we got the new rudder bearings machined, aligned and epoxied in place, with release tape around them

to facilitate removal. Houa made good progress in the aft cabins, replacing some water‑damaged

wood, remounting the headliner supports, building a new bed to repair the whale‑damaged one and

extending both aft beds a few inches. Jon completed several small jobs - a drain‑hole in the

port topsides was found and opened up, 6 drain‑holes were de‑cored and filled, several tools were

repaired, and much of the starboard gelcoat lip was faired. Sue and Amanda put in lots of time

polishing the mast, and Amanda chipped back some gelcoat that wasn't adhering correctly on the port

sugar‑scoop.

P'Wat spraying the bows and the trampoline holders |

Week 70, March 4 - March 10, 2013:

Baw wet‑sanded the forward half of the port topsides through 2000, and it's looking very nice.

But the aft half of port topsides needed to get rough sanded and re‑sprayed, as it was a bit

translucent. The starboard topsides were wet‑sanded up through 1000 and then all the many

little pin‑holes were filled with dots of gelcoat. The insides of the hulls and under the

bridge‑deck were filled and faired and prepared for gelcoat. The trampolines were dug out,

suspended where they'll eventually go, and holes were drilled in the support tubes for the lashings.

The holes were then opened up into nicely rounded vertical slots, but we noticed that the rods that

Golf put in there are too short. Amanda found that she could chip off some of the gelcoat up

on deck. It obviously isn't adhering properly and will also have to be re‑sprayed. We

finished rough‑polishing the corrosion out of the port side of the mast and started polishing it.

Houa built the new bed for the port aft cabin, complete with opening hatches, and coated it all with

epoxy. Then he bought sheets of rubber and foam to build sound and thermal insulation to go

under both aft bunks. Our life‑rings were taken to Rolly Tasker to get recovered.

Unfortunately, Sue broke her wrist jumping off a drum and it will be in a cast for a month.

The good news is that Mike and P'Wat sprayed gelcoat on the port aft topsides as well as the entire

area between the hulls! The guys immediately started sanding the new gelcoat before it got too

hard. A hash‑pipe was found in our work area, and Jack and Chai were moved to other projects

in the yard and we got 2 new workers, Beng and Nai.

Sanding (rock hard) gelcoat above your head is harder work! |

Week 71, March 11 - March 17, 2013:

Most of the guys worked under the bridge‑deck all week, wet‑sanding the new gelcoat - a difficult

job as they have to work over their heads. Baw tried a pneumatic sander for a while until it

blew a bearing. Lek worked alone, sanding the aft half of port topsides, another area that was

sprayed last week. He got most of it to 400, so we want the dots filled before they go to

finer grit paper. Team Hacking made excellent progress on the mast (despite Sue's left arm

being in a cast), getting the whole thing polished, most of it sanded to 600, and the top half

(above the second spreader) sanded to 1000 and coated with Nyalic! Houa worked in the aft

cabins, repairing and epoxying in the bed in port (old whale damage), adding new access hatches

under the bed, sticking on new sound insulation, enlarging an access panel so we can get to the

fill‑pipes for the port diesel tank, and repairing the starboard engine access hatch. Several

side‑trips were necessary: Sue had to replace her initial cast with one more permanent, and she had

to get her expiring passport replaced. Jon spent a morning helping friends remove their masts,

and on Sunday those friends hosted a wonderful BBQ/pool party.

Love the reflections in the polished gelcoat under the bridge-deck |

Week 72, March 18 - March 24, 2013:

Lek did a great job on the port topsides, working all by himself as he wet‑sanded with 400, 600, 800,

and 1200 grit paper, repairing the inevitable small gelcoat defects along the way. Jon

started sanding the gelcoat at the waterline, fairing it into the hulls. This turned out to be

a tough job that he eventually handed off to Nut. He also spent time polishing the mast

spreaders and finger sanding the fiddly bits at the base of the mast. Houa built up some

4‑layer sound insulation and glued it to the undersides of both engine hatches. He reinforced

the starboard aft bed and replaced all of the headliner supports in all 4 cabins, modifying them to

go around our new hatches. Then he started removing some of the damaged wood from the middle

of our old cockpit table. Baw, Nut, and Pla spent much of the week wet‑sanding under the

bridge‑deck, another difficult job. But on Friday they were able to polish the aft section,

which lifted everyone's spirits. Bank and Yoong wet‑sanded the insides of the topsides, making

good progress. Sue sanded much of the mast 1‑handed, but making great progress, and on Sunday

she and Jon were able to paint Nyalic from the 2nd spreader down to the rope‑clutches.

Amanda spent much of the week chipping away at poorly adhered gelcoat on top of the cabin, a

distressing discovery. The yard buried a tire with a rope around it for us, giving us a better

support for our tent.

2 strips of teak, held by wedges, being epoxied into the table |

Week 73, March 25 - March 31, 2013:

Boy and his wife Kit started working for us - a delightful, hard working and talented couple who speak English pretty

well. Kit did intricate detail work on the mast and then jumped down into the port engine room

and cleaned it thoroughly. Boy helped Jon remove and replace the 4 toilet‑out sea‑cocks and

also went with Jon on a great spending spree, buying lots of plumbing fittings in town. Jon

used those fittings to put together a pair of diesel manifolds for the new forward tanks, and also

cut out and de‑cored 2 engine‑room vents and the 2 aft shower holes, and drilled out and installed

12 PVC nipples in the cockpit that will become 6 more cockpit drains.. Houa bought teak planks

for the cockpit table and started tearing apart the 2 sides that need work, epoxy sealing the good

wood and gluing new teak into one of the sides. On Tuesday a pickup truck pulled out right in

front of Jon, causing him to smash into the side of the pickup. Jon was not badly hurt, but

the scooter needed work, which the driver's insurance company paid for. Lek continued

wet‑sanding the port topsides and then joined Pla and Nut sanding off the repair bumps from the

starboard topsides. The rest of the team spent much of the week chipping off poorly adhering

gelcoat from the deck and cabin‑top. The problems are more extensive than originally thought,

so we've decided to have AME prepare the cockpit and sugar‑scoops, so they'll take full

responsibility for everything working. Unfortunately, some miscommunication caused them to

only come 1 of the 3 days they were planning to. Amanda's college house‑mate Liz visited so

Amanda didn't come in much this week, preferring the beaches and bars of Phi Phi Don, but she and

Sue did get 2 layers of Nyalic on most of the spreaders as well as the base of the mast.

Jon's birthday dinner party - MUCH more food came out later |

Week 74, April 1 - April 7, 2013:

A productive week. Jon made up and installed 2 diesel fuel manifolds up forward, next to our

new tanks, and 2 back in the engine room. Jon also replaced the fiberglass rods in our

trampoline supports with longer rods of the correct size. Amanda joined Jon in assembling the

mixing valves for the bathrooms. Houa finished epoxying in teak planks into our cockpit table

and the 2 halves were wrapped up and stored. Then he started repairing the teak lattice

between our trampolines. Pla and Lek moved around the topsides, filling gelcoat pinholes and

wet‑sanding with ever finer grades of sandpaper. Baw and Yoong, and Nut and Bank before they

left the team, scraped off almost all of the gelcoat that had been sprayed on the decks, a huge job.

Sometimes it was underlying filler that came off, but sometimes it was just the gelcoat, obviously

sprayed on inadequately prepared surfaces. Baw and Yoong then sanded the edges to fair

everything in, and put down thick vinyl where the nonskid will go so they know where to walk and

where not to walk. P'Wat showed up to prepare the cockpit and sugar‑scoops, but he also didn't

prepare the (epoxy) sugar‑scoops adequately, and the filler he put down was very soft, so Mike took

over those jobs. Hem, our mechanic, arrived and removed the raw water pumps from the engines

so he could install better impellers and seals. Sue finally got her cast off, but her arm

still hurts and she can't work with it much, although she documented our progress and sanded some

mast bits. The filler on the transoms was ground off and replaced with several layers of

fiberglass and phenolic filler. Amanda continued polishing the forebeam and the spreader bars.

On Sunday the spreader bars got a good coating of Nyalic, and much of the mast got a second coat.

The valve cover-plate had to be trimmed down to fit, but it's in! |

Week 75, April 8 - April 14, 2013:

Hem, our diesel mechanic, finally returned to finish a couple jobs that Jon wanted done -

rebuilding the salt‑water pumps with the correct Yanmar parts and installing our 2 new

Jackmaster bypass oil

filters. Jon spent a lot of time in the bathrooms, installing the new water mixing‑valves for

the sinks and showers. He also repaired an area where water was getting in back at the

transoms. Yoong and Baw and Nut sanded virtually all of the deck and cabin‑top, smoothing down

the edges of the chipped‑off gelcoat and applying filler where necessary (and being extra careful

about cleaning and adhesion). Then they moved on to sanding some of our hatches and cleaning

the fo'c's'les and grinding underneath our keels and washing the underwater areas in preparation for the epoxy barrier coats.

Phuket Fiberglass delivered 50 liters (13 gallons) of epoxy for that underwater barrier coat.

Lek and Pla finished the pinhole repairs and sanded the topsides up to 1500 grit, then they cleaned

and painted the undersides of the engine hatches. Sue and Amanda worked on polishing the

forebeam and the anchor support beam, and Sue spent a lot of time in the apartment, working on our

taxes. We turned the mast on its back and started cleaning up bits of mast hardware.

Houa spent the week rebuilding the teak grate that goes over the anchor support beam, between the

trampolines. Mike brought a team to prepare the swim‑platforms for gelcoat, and spread some

soupy epoxy on to level them out.

Houa finishing up the assembly of our teak lattice |

Week 76, April 15 - April 21, 2013:

Houa finished most of the hard work on the teak lattice that goes between Ocelot's trampolines - cutting out

the teak strips, routing them out, fitting them together, and epoxying them into their frame.

He also added more teak and ash (no holly here) to one of our floorboards. Baw and Pla

prepared much of the cockpit for gelcoat, sanding and filling all the many fiddly bits. Jon

found that some serious work was needed on the floor of the cockpit lockers so Baw and Pla ground

off the bad gelcoat, then removed and replaced some delaminating glass. Lek sanded the

helm seat and the engine hatches, getting them ready for gelcoat. Then he built up and painted

the edges of the cockpit hatches, to better support the teak that will go on top of them. Lek

and Pla spent some time on the cabin‑top, filling dips and sanding chipped edges smooth.

Amanda rough polished the anchor support, boom, and forebeam, but then a grinder attacked her so she

moved over to help Jon on the mast. They untangled and rearranged the halyard chaser lines in

the mast and pulled all of the main PVC wiring conduit sections up the mast. Our new Dynex Dux

diamonds need special mast fittings, so Jon opened up 8 thimbles to put over spreader‑tips.

With the changing monsoon, Jon reinforced our tent supports for SW winds. Sue dug out our mast

bits and started cleaning them up, helped rough polish the spars, and also helped Jon with the mast

wiring conduits.

The 4 templates on the 4 starboard sugar-scoop steps |

Week 77, April 22 - April 28, 2013:

A major change of direction - Mike (AME) agreed that instead of spraying gelcoat around where the nonskid will go,

then sticking the nonskid down and then spraying more gelcoat around the edges, it would be simpler

if the nonskid went down first and then he could do a heavy spray of gelcoat around the edges of the

nonskid. This would save lots of masking and sanding, give us one fewer layer on the deck, and

probably save all concerned both time and money. So Baw and Team Hacking spent the week

preparing for the nonskid - marking off the borders of where it will go, smoothing the existing

deck, laying parallel alignment lines down the deck, and building the first 10 templates for Mike to

use for cutting out the nonskid panels. Ben and Lek worked under Ocelot, sanding and painting

the undersides of the cockpit hatches and the shelves from the scuba locker and the fo'c's'les.

Houa finished both the teak lattice and the broken floorboard he's been working on. He put

gaskets on the engine hatches so they could be put back in place, cut 3 sheets of 3mm plywood into

thin strips for the templates, routered out the areas for the swim‑ladder hinges, and made 10mm

plywood covers for the other 14 deck hatches so we won't risk falling through one. Pla worked

on the cockpit lockers, putting a thick layer of epoxy filler and some glass on the floor, and

spreading polyester filler on the walls to smooth them out.

Houa planing a nice face on one of his big teak boards |

Week 78, April 28 - May 5, 2013:

Work focused on 3 areas this short, Labour Day week: our new teak, the cockpit, and the nonskid for

the deck. Houa bought $2,000 of big teak blocks and spent the week making expensive sawdust -

cutting the teak into strips for the teak floor in the cockpit, planing the strips flat, and routing

a groove in the edges. He ended the week with 75 nicely planed and prepared teak boards ready

to cut down to size. Baw, Pla, and Lek spent much of the week in the cockpit, preparing it for

Houa's teak, measuring the edging and building it up where necessary, filling the bottom so it's

flat and the right height, and sealing the filler with waterproof epoxy resin, all to Houa's

exacting specifications. They also cleaned out the dive and rope locker, and epoxy sealed the

frames that hold the shelves up in there. Jon and Amanda laid out exactly where many of the

nonskid panels will go on the deck, and made careful templates of the first 32 areas, almost half of

the 75 templates we'll need. This is a frustrating job, as they need to plot where the deck

hardware will go, and they've got to show how all the nonskid diamonds need to line up, when Ocelot

has very few straight lines. Baw's brother Ben spent most of the week in the port fo'c's'le,

sanding and cleaning it to paint. Sue, our photographer, split her time between taking

pictures and polishing the forebeam supports, the anchor beam support, and the forebeam itself,

which she was able to Nyalic on Sunday.

Laminating strips of teak together in a curve for the eyebrows |

Week 79, May 6 - May 12, 2013:

Some good achievements this week. Houa built a beautiful pair of curved, laminated teak

rain‑gutter eyebrows, one to go over the entryway and the other over the galley window. Each has several

improvements over the originals. Houa also made 3 teak mounting blocks to replace the old

plywood ones under our spinlocks and turning‑blocks. Pla and Baw repaired the last of the

whale damage in the port engine room. Then they ground back and reinforced 5 of the 8 areas

around the rudder‑tubes with 4 layers of fiberglass (with Jon doing the last 3 areas). The

fiberglass still needs to be sanded and painted. Baw and Lek spent much of the week preparing the cockpit for gelcoat spray, scheduled for next Monday.

This is a high priority so Houa can start laying down the teak flooring in the cockpit. Dui

and Ben and Pla had the really grotty jobs - smoothing the old gelcoat in the fo'c's'les and

the chain lockers, to prepare them for painting. Jon and Amanda spent much of the week drawing

out exactly where we want the nonskid to go on the foredeck, and making up templates so Mike can cut

the nonskid to the correct shapes. As part of that they found where a reefing pad‑eye has to

go at the base of the mast, and ground back the filler so it could be mounted flat. Jon

de‑cored the anchor‑winch bolt‑holes, but they still need to be filled. Sue made good progress

polishing spars and sorting and cleaning bits and pieces. With Amanda she took a complete

inventory of the bits stored in our apartment. Team Hacking also worked out now many mast

steps we want (27) and where they need to go.

Baw shooting gelcoat into our big under-cockpit lockers |

Week 80, May 13 - May 19, 2013:

A productive week! On Monday, Mike started and Baw finished spraying much of the flooring area of the cockpit with gelcoat.

Then Mike loaned us his big gelcoat gun and Baw got on a gelcoat spraying roll. On Wednesday

he sprayed the big deep cockpit lockers, on Thursday he shot the aft‑deck, lazarettes, and helm

seat, and on Friday he shot the chain lockers and the entryway steps! AME's machinists drilled

out our 14 mast tangs and (eventually) pressed in stainless steel inserts. The fo'c's'les and

one chain locker were painted with primer. We found that the Nippon epoxy paint sold to us by

cruising friends doesn't perform well at all, and a lot of time was spent removing it. We

decided to use Sikaflex to stick down the teak in the cockpit, instead of epoxy, and Mike delivered

2 fresh cases from Bangkok to put in our fridge. We removed the vertical davit supports and

Mike took them to the powder coaters to get painted. Jon and Amanda built a small mold and

glassed up a shelf for the washing machine. They also de‑cored and filled the bolt‑holes for

the anchor winch, and worked feverishly (between gelcoat sprays) to finish the difficult curved

nonskid templates. We bought more acrylic and Houa cut it up to make more of our toothbrush

holders. Houa also started making the long toe‑rail to go across the aft‑deck, behind the

cockpit. On Saturday we left early to visit friends in Ao Po to begin a weekend‑long

celebration of our 34th wedding anniversary.

Lek and Baw finished the aft cabin-top to 1500 grit! |

Week 81, May 20 - May 26, 2013:

On Monday we celebrated our 34th wedding anniversary - and put Amanda on a plane back to the US. We miss

her already. Baw shot the front of the cockpit with gelcoat, then his team took down the

masking and spent the rest of the week sanding and polishing the cockpit gelcoat. Ben joined

the cockpit team once he finished sanding the helm seat. Jon and Amanda managed to finish the

worst of the curved nonskid templates before she left. Houa finished the aft‑deck foot‑rail,

then started building the inside trim for our 2 new hatches, making a mold from some of our other

trim first, so the trim pieces should all look the same. Jon and Sue got a lesson in stainless

steel from Mike and Wiwat, but we need to find out if we can get our swim ladders electro‑polished

in Bangkok. Later, Jon and Sue worked on the nonskid alignment lines for the louvers, looked

for appropriate plastic to line our anchor well, and removed the horizontal davit supports for Mike

to get powder‑coated, replacing the supports with temporary PVC pipe. Sue continued polishing

the boom and forebeam. Jon sanded and filled the chain‑locker hatches, prepared to glass on

the washing machine shelf in the port fo'c's'le, repaired a broken wire on the autopilot motor and

mounted the motor and reduction gear, got all the supplies to add new drains to the battery hatch

gutter, and dug trenches and walls so the rainwater drains away from Ocelot. On Friday and

Saturday we got some pretty torrential rains, so we're now officially in the wet season.

Houa, Baw & Jon fit the new motor onto our compressor |

Week 82, May 27 - June 2, 2013:

A lot of cockpit work this week, first sanding the gelcoat but then adding filler to the big beds on either

side, smoothing them down, and spraying more gelcoat on the beds and the entryway. But instead

of borrowing E‑Us compressor, we finally broke down and replaced the motor on our compressor (and

repaired the cracked engine mounting bracket). Baw also sprayed the rope/scuba shelves, the

4 internal fo'c's'le hatches, and the 4 plastic‑wood pieces that go in the bathrooms. Houa

spent some time trying to create the interior trim pieces for the 2 new forward hatches but got

frustrated so we asked him to install the acrylic in our 10 newly powder‑coated deck hatches and

2 big fo'c's'le hatches instead. Sue is learning to use the scooter more so she published her

scooter driving instructions. Sue also spent many hours sanding and polishing the forebeam and

sorting and cleaning all the many bits for the hatches. Jon filled and sanded the old handle

holes on the 2 chain‑locker hatches, and mounted our washing machine shelf in the port fo'c's'le.

Mike delivered the many nonskid panels that he's cut, sold us a new liferaft, showed us a sample of

the mast steps he's making for us, and showed us samples of the 316 hose‑clamps that AME carries.

Houa preparing cabin-top panels while Baw works on portside |

Week 83, June 3 - June 9, 2013:

A high energy week of preparing and gluing nonskid panels to the deck. But on Tuesday Sue

slipped on a plywood hatch cover and fell through the opening, cracking a rib, so she recuperated at

the apartment for the rest of the week. Mike from AME brought helpers for a couple of days to show

our guys everything to do. Shapes were corrected, edges straightened, backs cleaned, alignmnet

checked, decks were sanded, cleaned and masked, wood battens cut, and heavy water-jugs schlepped.

Mike gave a quick demonstration for everyone on a small hatch, with Wiwat providing translation for

our men, and then we started on the decks in earnest. We started in front of the salon, by the

anchor winch, and moved out and down the decks. By weeks end we'd glued down 26 (of ~80)

panels. Pla, Lek and Ben continued sanding the cockpit gelcoat while the AME guys were with

us. Once the pieces were down, some needed glue picked out from around the edge, then they

were re-taped and masked with thick vinyl.

The cockpit is getting cleaner and whiter every day |

Week 84, June 10 - June 16, 2013:

A bit of a washout week, as it rained almost every day, several workers stayed home on Monday and

Tuesday, and Sue's cracked rib kept her out of action for the first half of the week.

|

Houa laying a nonskid panel on the top sugar-scoop step |

Week 85, June 17 - June 23, 2013:

A good week, as we glued down a lot of the nonskid. Even the weather cooperated, with little

rain in this, the rainy SW monsoon season. This week we:

|

Mike checking wood stiffeners on the swim-platform carbon |

Week 86, June 24 - June 30, 2013:

An absolutely beautiful week weather‑wise, as we had no rain at all. This week we:

|

After sanding, the Golden Teak looks really nice |

Week 87, July 1 - July 7, 2013:

A good week, despite all the rain. This week we:

|

Baw, justly proud of his varnish in the starboard forward cabin |

Week 88, July 8 - July 14, 2013:

A good week, despite having to fly to Bangkok for a day to renew our visas, but on Sunday we

celebrated "The Day All of France Celebrates Sue's Birthday." Other accomplishments for the

week include:

|

Baw spraying more epoxy on the cockpit table halves |

Week 89, July 15 - July 21, 2013:

Good progress all week despite Jon's absence to join in Phuket Race Week (sailing a 28'/8.5m

Firefly catamaran) but some sideways steps on Saturday. This week we:

|

Starboard shoulder piece, with Jon filing open a rope hole |

Week 90, July 22 - July 28, 2013:

Some good accomplishments this week, despite a 3‑day Buddhist holiday. But Jon's broken

finger from the end of last week certainly slowed him down, as he can't (or shouldn't) really use

his right hand. Our accomplishments for this week include:

|

Ocelot with new epoxy on her bottom |

Week 91, July 29 - August 4, 2013:

The big push this week was getting the hulls cleaned and sanded so we could apply our epoxy barrier coat

below the waterline, and do it before the forecast rains halted all epoxy operations. This

week we:

|

Receiving the big, gooped up sheet of nonskid for the bimini |

Week 92, August 5 - August 11, 2013:

Our big accomplishment this week was that we (finally!) finished gluing down the nonskid!

WOOT! Our other accomplishments this week include:

|

Lek sanding the cabinet doors, preparing them for more varnish |

Week 93, August 12 - August 18, 2013:

The major push this week was varnishing. Most of the doors were sanded under

Ocelot's stern, and the varnish was applied in 2 varnish tents, one under Ocelot and the other under

a neighboring cat. This week the team:

|

Polishing the cockpit table - reflection is a neighbor's mast |

Week 94, August 19 - August 25, 2013:

The guys continued their varnishing, making excellent progress, but several other projects moved forward as well.

This week:

|

Baw sprayed 1 coat, waited 5 min, then sprayed a 2nd coat |

Week 95, August 26 - September 1, 2013:

Another varnishing week, but most pieces got finished. This week the team:

|

Beautifully varnished doors waiting to be installed |

Week 96, September 2 - September 8, 2013:

This week we tried to wrap up the varnishing so we could move to gelcoating the deck, between the

nonskid panels. This week the team:

|

Baw spraying gelcoat on Ocelot's foredeck |

Week 97, September 9 - September 15, 2013:

Rain delayed us for a few days in the middle of the week but we ended up getting in three gelcoat

spray days, shooting the entire cabin‑top and foredeck (without Mike's oversight). But we had a major problem with

the 2 curved and very visible (and somewhat irreplaceable) locker doors in the salon. The team's

accomplishments this week include:

|

Afterwards, a newly sprayed starboard deck! |

Week 98, September 16 - September 22, 2013:

The big accomplishment this week was spraying the entire starboard side‑deck with gelcoat - a big job.

Other accomplishments this week include:

|

Ocelot's portside & stern, with the growing spray-tent |

Week 99, September 23 - September 29, 2013:

The biggest accomplishment this week was that we finished spraying gelcoat on the decks!

WOOT! Other accomplishments by the team include:

|

Everyone working while the boss (Baw) doodles with a pen... |

Week 100, September 30 - October 6, 2013:

A very wet end of the week spoiled some varnish and prevented us from finishing the rudders, but

the guys made excellent progress sanding and polishing the decks, especially with the 2 extra men.

This week's accomplishments by the team include:

|

Baw, Jon and Heru wetting out another sheet of biaxial |

Week 101, October 7 - October 13, 2013:

This week was our third Vegetarian Festival, which is not at all what it sounds like. But the main

boat work was sanding and polishing the deck and the sugar‑scoops. Other team accomplishments include:

|

Spraying the bimini "gutters" between the sheets of nonskid |

Week 102, October 14 - October 20, 2013:

A productive week, as we had lots going on and a good team. Accomplishments this week

include:

|

The bimini is snuggled into place on the targa-bar |

Week 103, October 21 - October 27, 2013:

Another good week! Not only did we finish and install the rudders, we all but finished the

gelcoating and we mounted the bimini up where it belongs! Team accomplishments this week include:

|

Our motley crew, having fun with LOTS of good food! |

Week 104, October 28 - November 3, 2013:

An emotional roller-coaster week with several frustrations, but we moved doggedly ahead, despite a

worker walkout on Tuesday. Our main accomplishments were to bolt the back of the bimini to the

targa‑bar and a lot of polyurethane sprayed on the floorboards. Other team accomplishments

include:

Frustrations:

|

Starboard went easily, port took some grunting (but no winching) |

Week 105, November 4 - November 10, 2013:

Most work this week focused on the salon, the heads, the spreaders, and several shelves, but the exciting

stuff happened around the forebeam. Team accomplishments this week include:

|

Whole lotta mast sandin' goin' on |

Week 106, November 11 - November 17, 2013:

The main thrust of the week focused on preparing the mast for painting, but lots of other good things

happened as well. Accomplishments this week include:

|

Baw & Heru having fun with the polished brass(!) cabin lights |

Week 107, November 18 - November 24, 2013:

The threat of rain delayed many things this week, even though the heavy rain didn't materialize until Saturday.

But we still made progress on several fronts. Accomplishments this week include:

|

Starboard trampoline laced tight, port still unstrung |

Week 108, November 25 - December 1, 2013:

A great week, as lots of projects were completed. There's lots for Jon to do and the trick

is finding things the workers can do, but for now they're all being kept busy. Team

accomplishments this week include:

|

"Tuning" the mast - note sighting board with nylon string |

Week 109, December 2 - December 8, 2013:

A very productive week, with many projects coming together! The projects are smaller now, so

hopefully we'll be able to finish them faster. Team accomplishments this week include:

|

The new gelcoat in the salon looks wonderfully clean! |

Week 110, December 9 - December 15, 2013:

The jobs are getting smaller, so in theory we can finish them faster. This week focused

mostly on sanding and gelcoating the subfloor of the salon, and working on our dinghy, Tomcat, but

many smaller jobs were also worked on. Team accomplishments this week include:

|

Baw spraying enamel around the floor of Tomcat |

Week 111, December 16 - December 22, 2013:

Good progress this week on several fronts - the teak cockpit floor was sanded and repaired, the

bilges got cleaned and painted in gelcoat, the deck hatches were stuck down, and Tomcat, our big

dinghy, got lots of pampering. Team accomplishments this week include:

|

Lunch with Daryl & Loretta at a beach restaurant in Nai Yang |

Week 112, December 23 - December 29, 2013:

A short week with a delightful Christmas break in Nai Yang with good friends in the north end of Phuket, but

we still got lots of good things done. Work focused on gelcoat repairs on deck, gelcoating the

bilges, mounting our newly electro‑polished stainless steel from Bangkok, and repairing some varnish

in the salon. Team accomplishments this week include:

|

Trimming the central hatch so it closes, all 3 big hatches open |

Week 113, December 30, 2013 - January 5, 2014:

Another short week, as we're now down to 5 workers (Houa, Baw, Pla, Heru, and Yando) and several didn't

show up around New Years. But we still made good progress, despite most businesses being

closed. Most work centered around gelcoat touch‑ups and cockpit hatches. Team

accomplishments this week include:

|

The portside bimini epoxy injections went much as planned |

Week 114, January 6 - January 12, 2014:

Bit of a slow week, as we're having trouble finding things the guys can do with minimal supervision,

so the jobs are smaller.

The week focused on the headliners, touching up the gelcoat around the nonskid, repairing the gaskets for the hatches,

and preparing the bimini for its new legs. Team accomplishments this week include:

|

Last bits of (blue-taped) stern armor stuck down |

Week 115, January 13 - January 19, 2014:

Again, a week of mostly small jobs, but they all need to be done. The main focus was putting

the stainless steel "jewelry" on the swim‑platforms, but we also made significant advances in the

bathrooms, headliners, and the bimini. Team accomplishments this week include:

|

Shooting 5200 under where the (raised) bimini leg will go |

Week 116, January 20 - January 26, 2014:

The big accomplishment of the week is that we finally got the bimini legs bolted onto the bimini and

onto the deck, which clears the way for several other jobs. The headliner project also got a

lot of attention, and it's taking a lot longer than we expected, but it is moving. Baw and

Heru both expanded their talents to new (for them) jobs. Team accomplishments this week

include:

|

Ocelot is getting more put together every day! |

Week 117, January 27 - February 2, 2014:

A busy week of plumbing projects, cockpit projects, dinghy projects, and headliners. We're

down to about 3½ workers, but we're actually making excellent progress. Team accomplishments

this week include:

|

Assembling all the roller gear sections on the headstay |

Week 118, February 3 - February 9, 2014:

This was largely a week of deck fixtures and headstay roller gear, with some interior varnishing

and headliner work as well. We have a nominal splash date of early March, so we're

hustling to get everything done. There were a couple of setbacks, but that's to be expected,

and we made good progress. Accomplishments by the team this week include:

|

Heru and Baw traded off using the heavy polisher |

Week 119, February 10 - February 16, 2014:

The big pushes this week were polishing and waxing Ocelot's topsides, including under the bridge‑deck,

and preparing the salon headliners for installation. We also completed much of the

electrification of the mast, and finished mounting the big cleats and bollards. Team

accomplishments include:

|

Jon and Heru working on a jammed pull-through string |

Week 120, February 17 - February 23, 2014:

A good week, as we charge headlong to a hoped‑for 3 March splash. The work this week focused

mainly on getting the mast and boom ready to mount (outside) and the salon headliners (inside), but many other projects were

completed along the way, despite being down to only 4 workers these days. Team accomplishments

this week include:

|

Once the mast was in position, we had to tighten up the rigging |

Week 121, February 24 - March 2, 2014:

Goodness - so much accomplished as we head for a March 3 launching. The big items were

putting on the antifouling, finishing the salon headliners (a huge job), dismantling (and selling!)

the tent, and erecting the mast.

But the list of smaller jobs is much longer. Team accomplishments this week include:

|

Ocelot is pushed into the (thankfully) calm ocean |

Week 122, March 3, 2014 and on:

Launched! Now the real fun begins...

Thai Refit:

Ocelot Pages:

Top Level: Home | Destinations | Cruising Info | Underwater | Boat Guests | Ocelot | Sue | Jon | Amanda | Chris | Site Map | Make a Comment

|

If our information is useful, you can help by making a donation |

Copyright © 2000‑ Contact: Jon and Sue Hacking -- HackingFamily.com, svOcelot.com. All rights reserved.