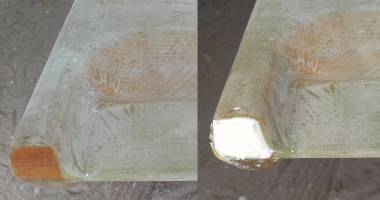

Water beads up on the left, where Nyalic was applied

54 Sink Cabinet

Water beads up on the left, where Nyalic was applied |

Summary: A slow week, as Houa couldn't work on Monday and Friday, and Baw quit the team on Tuesday (we eventually found that Golf hadn't paid him). Our Nyalic test worked well, but then Amanda went off gallivanting around Cambodia with a friend. Baw spread a bit of gelcoat on the cabin‑top, but later we found this is not the good quality isophthalic gelcoat that we'd paid for. Golf had taken our $1,000 but only bought cheap gelcoat, and presumably pocketed the difference. Houa made good progress in the galley, building the front facade and lowest shelf for the sink cabinet. Jon mounted the hinges and finger‑pulls on the 2 forward hatches in front of the main cabin, and trimmed the edges of the hatches down so they clear the water‑catching gutters under them. Jon also worked on the targa‑bar, finding the center‑line, putting the solar panels back, mounting 3 sets of blocks and their mounting plates, and drilling and tapping all of the mounting holes for the main‑sheet track. Sue sanded another section of the mast, so it's almost ready for Nyalic, but she also put in a huge amount of work on a big spreadsheet of our costs for this refit. From this we were able to determine very accurately how much Golf has spent on Ocelot - about $30,000 or roughly half of what we've paid him. We had some long conversations with Golf about what has happened with the rest of our money but we're not sure he really understands what will happen if he fails us, or how successful he'll be if he makes us happy.

Baw applying gelcoat on the starboard cabin-top |

Monday, November 12:

Bit of a slow start to the week. The power was out for much of the day, which didn't help

productivity. And Houa showed up but claimed to be too sick to work and went home. At

least he left a $350 list of supplies he needs to put the galley back together.

The good news is that we got a new worker. He doesn't seem to know much about boat work, so he'll need constant supervision, but it's a small step in the right direction.

Whomping on stuck bolts with an impact screwdriver |

The other good news is that our Nyalic seems to be doing well. It was interesting to see the water beading up where we'd applied the Nyalic, and spreading out elsewhere. We'd hoped that Amanda would be able to finish they whole section between the first and second spreaders, but she's leaving for Cambodia tomorrow and ended up spending all day sorting and packing.

We had a discussion with Golf about how to do our decks and the antiskid. We were thinking that the decks were already smooth enough, and that we could build the antiskid out of gelcoat (for the textured surface) with an epoxy/fiberglass backing. This could then be stuck down to our epoxy decks with epoxy, and the only epoxy/polyester transition would be in the antiskid itself.

But Golf was not happy with this. He's used to putting gelcoat down on the decks, smoothing that out, and then sticking the antiskid down onto the gelcoat with polyester. This means building the antiskid entirely out of polyester (gelcoat is a polyester with fillers), and it puts the epoxy/polyester transition where the decks are now.

Houa positioning the new stainless steel sinks in the galley |

We're not big fans of polyester and usually do whatever we can in epoxy. Epoxy is stronger and has better adhesion. But epoxy doesn't have ultraviolet (UV) inhibitors, and yellows in the sun. More importantly, Golf is the expert here. We're paying for all the materials at this point, so costs are all the same to him (epoxy is much more expensive than polyester) but he prefers to go with polyester for the cosmetic layers. OK...

So Baw and the new man spread gelcoat on some exposed parts of the starboard cabin‑top, especially where the grab‑rail used to be and the new step.

The new floor of the sink cabinet (manual foot-pump on right) |

Jon was working back on the targa‑bar. First he cut back some fiberglass that had crept where it shouldn't, then he removed the plastic protecting the solar panels. We want to mount the main‑sheet track back on top of the targa‑bar, but some of the bolts are still stuck in the track, so Jon whomped on them for an hour or so with his impact screwdriver and eventually got them free.

Sue spent much of the day working on a spreadsheet of what we've spent on this refit. We're isolating each job so we can report to Golf what each job actually cost. We also want to generate some graphs of how much we've paid and how much has been spent on Ocelot.

Tuesday, November 13:

Houa was his normal chipper self today, but Baw only put in half a day - not sure why or where

he went.

Preparing to remount the solar panels to the targa-bar |

Tonight we had a delightful evening out on the water, having drinks and dinner with new friends on the deck of their trimaran. They'd been sailing hard for the last 3 months. In Chalong Bay the breeze was soft and cool, the sunset was colorful, the Big Buddha was lit up on top of the hill, celebrations were going on here and there ashore with fireworks and floating lanterns being released, and the stories told were fun and stimulating. It reminded us again how much we love the cruising lifestyle and the cruising community.

Amanda left today to go gallivanting around Cambodia with her friend Doug. So Jon lashed her pack to the front of the scooter and took her up to the bus station on the north side of Phuket Town. She'll be gone for 18 (long) days, but we're sure she'll bring back interesting stories and photos. Hopefully she'll post some of them.

Routing out Houa's epoxy filler from the finger-pull holes |

Houa worked on the sink cabinet in the galley. The sink cabinet was completely removed back in late January, as some of the wood was badly rotted in places. We had our stainless steel fabricator make us a new stainless steel countertop, with the sinks welded into it. Today Houa determined how high we want the sinks (basically, as high as possible). He also built up the lowest shelf of the cabinet out of marine ply and formica.

Baw spent the morning sanding down more of the gelcoat filler that he put on the cabin‑top, but it was pretty obvious that his heart wasn't in it. No sign of the new guy who was supposed to be helping him.

Solar panels bolted to the back of the targa-bar |

Jon was working on the targa‑bar. First he determined where the middle of it is, a surprisingly difficult task as there are few good reference points, and the edges are all curved. Then he centered the solar panels as best he could, and drilled new holes to attach the panels to the back of the targa‑bar. Once the mounting surface is cleaned, we'll mount it with 8 new stainless steel bolts and some marine silicone so water doesn't leak down.

Jon also routed out the finger‑pull holes in the 2 new forward hatches. After Jon dug out the foam (de‑cored) those holes last week, Houa had filled the holes with epoxy and filler, so they could be drilled and tapped. Now the finger‑pulls fit again - all they need is for the holes to be re‑drilled and tapped, and the finger‑pulls and hinges bedded down with silicone.

Houa masking his formica so he can epoxy coat the wood |

Sue had an administrative morning, working on our spreadsheets of labor and materials costs. At the end of it all, we'll have some very interesting statistics on how many (Thai) man‑days each of our mini‑projects took. Knowing that Houa needed some direction in the galley work, Sue went in after lunch so she was there to see his ideas on the height of the sinks. We also designed a lift‑out trap door in the floor of the sink cabinet so that we can retrieve small things that sneak between the floor and the foot pump assembly, or to dry out any water that finds its way under there.

Wednesday, November 14:

No sign of Baw until the late afternoon. He says he'll be in tomorrow, but we asked Golf to

find out why he was out.

The new port forward hatch in position |

Jon pulled off a couple of minor but high visibility milestones. He started with the solar panels, cleaning up the face that bolts to the back of the targa‑bar and masking off the area around there. He opened his new tube of marine silicone, covered the contact area in a thick layer, bolted on the panels (with some Tef‑Gel to minimize corrosion between the stainless bolts and the aluminum mounting bracket) and tightened everything together. Then he shot a nice filet into the cracks and pulled off the tape to give a nice clean appearance. Strange how such an easy job gives such satisfaction.

Then Jon attacked the 2 forward hatches that go just in front of the salon ports, drilling out the bolt‑holes, tapping them, making sure everything went together smoothly, and bedding everything in silicone. He did this for the finger‑pulls as well as the hinges (with a quick trip to the local hardware store for more appropriately sized bolts). Mounting the other side of the hinges to the deck got a bit more complicated, as the edges of the hatches interfered with the gutters underneath them, but grinding down the edges until the hatches cleared the gutters and swung freely solved that problem. Now both hatches are mounted in about their final locations. We still need to spray the undersides with gelcoat, stick the gaskets on the undersides, and trim the gutters until the hatches sit on them uniformly, and, of course, gelcoat and polish the tops, but Baw can do most of that.

Jon bolting the main-sheet track to the top of the targa-bar |

Sue was back at the apartment all day, working on our job‑costing spreadsheet in the nice air‑conditioning. It's coming along nicely, but we need a few numbers from Golf, especially for supplies that he bought and expenditures he made early on. Unfortunately, with Sue not at the yard, not many pictures were taken...

Houa continued his work on the galley sink cabinet. We realized that we needed a way to access the area under the lowest shelf, so today Houa cut out an access panel and put little frames under it. Then he taped off all his formica and epoxy coated all the exposed wood, letting the epoxy soak in as long as possible to make the wood waterproof.

Houa screwing down the bottom shelf of the galley sink cabinet |

Thursday, November 15:

An unsettling day today. We're having trust issues with Golf, which is always bad.

We're not sure that he's using the correct high‑quality gelcoat that we paid him $1,000 extra for.

Baw was driving out with a big smile on his face as we came into the boatyard. We asked Golf what was going on. He said that Baw was sick with Malaria. Uh‑huh... When we talked to Houa privately later, he said that Baw wasn't sick, but Golf hadn't paid him. This seems much more likely, as today Golf had to make a $300 payment on his truck. <Sigh...>

We wish we knew all the undercurrents here, but Houa seemed as chipper as ever. Today he finished the bottom shelf of the sink cabinet and screwed it down in place. Since it has to go over the drain‑hose for the sink, Jon ran out to buy more hose and hose‑clamps, and Houa replaced it all for us.

Targa-bar hardware getting positioned & mounting holes drilled |

Jon worked on the targa‑bar, mounting the main‑sheet track. We've decided to tap the fiberglass and thread the bolts into the glass, with a lock‑nut underneath. The fiberglass is about 1" (25mm) thick where the main‑sheet track bolts down. Not only will this be stronger, but it will be much easier to seal the bolts so that no rain‑water leaks into the inside of the targa‑bar. The bolts won't get a chance to move or "work" if they're that tightly held in place.

We drilled out 2 bolt holes from underneath, one on each end, which located the main‑sheet track. Then we used the holes in the track itself as guides to drill the rest of the holes in the top of the targa‑bar. The backing for the main‑sheet track (inside the targa‑bar) used to be plywood covered in fiberglass. This is a bit short‑sighted - if the bolts leak a bit and water gets into the plywood, it will rot. This happened several years ago to the backing wood on port side, and we replaced the plywood with a thick chunk of (inorganic) fiberglass. Starboard side was still OK, but a few months ago we had Mee rip out the wood and replace it with fiberglass anyway, as that was a problem waiting to happen. Since starboard side had never been drilled out, Jon drilled those holes undersized and then tapped the holes, so they're essentially finished. The existing bolt‑holes on portside are too large, so Jon cleaned them out, taped over the bottom, and put masking tape around the top. Tomorrow we'll inject epoxy mud into the holes, and when it's cured we'll drill them out with undersized holes and tap them. Then we can do the final mounting of the main‑sheet track.

5 Bolt-holes filled with epoxy mud, to be re-drilled and tapped |

Friday, November 16:

Not much happening at the boatyard today. Baw is gone, Houa was working on our neighbors boat

for the day, and Sue was working on our costs spreadsheet in air‑conditioned comfort at the

apartment. So it was just Jon.

Jon had a long talk with Golf, pointing out that Golf has a huge opportunity in front of him. Enough cruisers read this website that if Golf makes us happy, cruisers will beat a path to his door, and he'll have as much work as he wants for a long time. But if he makes us unhappy, cruisers will read that as well and will avoid him. Golf owes us about $30,000 that we gave to him but which was not spent on Ocelot. But his only real asset (besides a few tools) is his beloved truck. If he sells his truck, he will have the money to honor his commitments to us. If he doesn't, he probably won't be able to work on boats again, and will have to go back to painting cars (for Thais, at Thai wages). Like many males, Golf is very attached to his truck, so this will be a difficult decision for him. We Shall See...

Back bimini corner: orange foam replaced with white epoxy mud |

Even as the only worker on Ocelot, Jon made some progress on the targa‑bar. Two stainless steel plates go under the bolts that hold the horizontal davit supports to the side of the targa‑bar. Problem is, those bolts were a bit difficult to get in and they're under a fair amount of tension, so Jon only wanted to remove one at a time so the other could continue to support the davits. As he unscrewed one bolt, he followed it with a bolt from underneath, so nothing would slip out of place. Slip the bolt all the way out, put it through the stainless plate, and push it back in, pushing out the "follower" bolt. It all went pretty easily once he worked out a system.

Jon heating targa-bar epoxy to cure it more completely |

Those plates also bolt into the top of the targa‑bar. Some of the holes were still small enough to tap, but some had to be drilled out so they could be filled with epoxy mud, re‑drilled, and tapped. A double‑block that handles the lines that position the main‑sheet traveler (the car that moves on the main‑sheet track) was also fitted and the holes drilled as appropriate.

For the holes that needed to be filled with epoxy mud, some duct‑tape was stuck on the bottom of the hole, to keep the epoxy from leaking out. The top of the hole was covered in masking tape and the hole cut out with a razor blade, so the epoxy wouldn't get on the new gelcoat. Before mixing up the epoxy, Jon also removed a bit of exposed foam from 2 places at the very back of the bimini, as he wanted to fill those areas as well.

The epoxy work went quite well. Jon made the epoxy‑mud pretty soupy, so he could pour it into his syringe. Then he injected it into the bolt‑holes, one by one. When the bolt‑holes were filled, he added more filler to the epoxy mud to make it thicker and smeared that into where he'd removed the foam at the back of the bimini. It will need to be sanded smooth, but at least it won't sag or fall out out as it's curing.

Houa and his facade for the galley sink cabinet |

Saturday, November 17:

Another slow day. We were supposed to have another meeting with Golf, to work out a plan for

how we're going to finish Ocelot. But Golf is now working on a couple of other boats, so

everyone was pretty distracted. Maybe Monday...

Houa was back working on Ocelot's sink cabinet for the galley. He laminated some formica onto some marine ply, and cut out the front facade, where the doors will go. The space is narrower than it was because the new stove is wider than the old one, so Houa was concerned that the doors may not fit, but apparently there's enough room.

Drilling & tapping mounting holes for the main-sheet track |

Jon checked his epoxy from last night and was disappointed to find that it was not as hard as he'd like it to be. We had torrential rain for much of the night, and perhaps the moisture and cooler temperatures impeded the cure. So Jon got a heat‑gun (like a hair‑dryer) and heated all his many little epoxy‑filled holes. By afternoon they seemed to have hardened enough to hold a bolt, so he drilled them all out and tapped them. Everything but the main‑sheet track got a dab of silicone in the holes and the bolts run home, with lock‑nuts underneath.

But the middle 3 bolts of the main‑sheet track connect to a bar that goes down to the back of the rear cockpit seat. This holds the targa‑bar from being pulled up under the (considerable) main‑sheet loads. So the lower end of the bar has to be fastened first, so the 3 upper bolts can tension the bar before the silicone sets.

Sue spent some time on finances and yard politics, then attacked the mast with wet sand paper. Using 600 grit gets rid of the mottled pattern from the grinder, and leaves nice long sanding strokes. To give it the finished look that we want under the Nyalic, we go over it with 1000 grit. She contemplated following up with the degreaser, denatured alcohol and Nyalic, but the wind was blowing too hard, and little bits of the casuarina trees were sprinkling down. Not a good time to put on sticky stuff!

TGIS: Thank Goodness it's Saturday. We ended this frustratingly slow week with a

lovely evening out at the local Phuket Cruising Yacht Club "Sand Bar" where we sat with our Aussie

buddies on a bamboo platform over the beach and enjoyed beers, fish and chips, and chicken

quesadillas. Did we say we're in Thailand?![]()

Thai Refit:

Ocelot Pages:

Top Level: Home | Destinations | Cruising Info | Underwater | Boat Guests | Ocelot | Sue | Jon | Amanda | Chris | Site Map | Make a Comment

|

If our information is useful, you can help by making a donation |

Copyright © 2000‑ Contact: Jon and Sue Hacking -- HackingFamily.com, svOcelot.com. All rights reserved.