Inner workings of a P/N junction LED (from Wikipedia)

LEDs

Light Emitting Diodes (LEDs) are rapidly becoming the preferred way to illuminate your boat. They're much more energy efficient than incandescent lighting, they last much longer, and they are now available in a range of eye‑pleasing colors, like warm‑white. They're even bright enough now for foredeck lighting. Several manufacturers are producing replacement bulbs, so switching over from incandescent lighting is easy. But before you run out and buy, there are some things you should know. For this article, we talk about the following subjects:

Less current draw: LEDs typically draw only 10‑15% of the current of an incandescent bulb Better luminous efficiency: The Lumens/Watt for LEDs (typically 100) is much better than for incandescents (typically 10‑15). Longer lasting: Incandescents last for 1‑2,000 hours, fluorescents for 15‑20,000 hours, but LEDs should last 35‑50,000 hours (and then they just get a bit dimmer) Many colors: LEDs are available in many colors, even infrared or ultraviolet, without using lenses over your light fixtures. No cycling problems: Incandescent (and fluorescent) lights don't like to be turned on and off too many times. LEDs have no problems being cycled on and off. Don't generate heat: You can hold most LEDs in your hand, but incandescents generate a significant amount of heat, which can be an issue in the tropics. Slow failure: Incandescents fail all at once when the filament burns out. LEDs usually just get a bit dimmer (unless you burn them out with a voltage spike). Shock resistant: The filaments of incandescent bulbs are quite delicate, but LEDs are solid state and very shock resistant.

Disadvantages of LED Lighting:

Higher Cost: LEDs have a higher initial cost than incandescents, much like fluorescent lighting does. LEDs and fluorescents last much longer than incandescents, but the payback may not come for several years, depending on your cost of electricity (usually very expensive on cruising boats). Harsh Color: Some LEDs can have a harsh, blue‑ish color that's unpleasant, much like a cool‑white fluorescent. But newer LEDs can be bought in just about any color you want. We've found that the warm‑white LEDs are actually a bit warmer (yellower) than the halogen bulbs they replaced, so they're very homey and pleasant (and your eye compensates, so it looks just like normal light). More Delicate: You'll damage or destroy an LED if you subject it to any sort of voltage spike. Incandescent lights are more tolerant of electrical abuse. Polarized Contacts: Incandescent lights will work no matter what orientation they're plugged in. LEDs are polarized and have to be plugged in the correct way. (Most newer LEDs, like G4 replacements, will work no matter which way they're plugged in) RF Interference: Some IC current limiting circuits can generate RF that can be heard in an SSB radio. See below.

History of LEDs:

According to Wikipedia,

LEDs were first invented around 1927, but not much was done with them for several decades until the

first practical consumer LEDs were introduced in 1962. They were initially relatively dim and

usually red, and they cost about $200 each. In 1968 Monsanto started mass producing

LEDs, which brought the prices down, and in the 70s Fairchild got them down to 5¢ each.

The first commercial LEDs were mostly used as indicator lamps and 7‑segment displays, first in expensive laboratory equipment then later in consumer appliances. These red LEDs were only bright enough for use as indicators. Readouts in calculators and watches were so small that plastic lenses were built over each digit to make them legible. Later, other colors grew widely available and started appearing in consumer devices. As LED materials technology grew more advanced, light output rose, while maintaining efficiency and reliability at acceptable levels. The invention and development of the high‑power white‑light LEDs led to use for illumination, which is fast replacing incandescent and fluorescent lighting.

Inner workings of a P/N junction LED (from Wikipedia) |

How Light Emitting Diodes work:

This explanation is just a thumbnail sketch aimed at non-technical types. For more information, see

Wikipedia's excellent article on LEDs.

Diodes are the electrical equivalents of a valve that lets electricity go in one direction but not the other. They're usually made of an extremely pure semiconductor material like crystalline silicon, where each atom has its outer electron shell only half full of electrons. One side of the silicon is then "doped" by having a tiny bit of material that has one additional electron in its outer electron shell baked into it, creating a surplus of electrons. This material is then called n‑type silicon, because electrons are negatively charged. The other side of the silicon is doped with a material that has one fewer electron in its outer shell, creating a shortage of electrons, or electron holes (called p‑type). When electricity is applied in one direction, the electrons and the holes move apart and no electricity flows. But when the electricity is applied the other way, the electrons and holes move together and the electrons fall into the holes and current flows.

Light Emitting Diodes (LEDs) work in much the same way except that they're made of more exotic materials. When the electrons fall into the holes, a bit of energy is given off in the form of light. The frequency (color) of that light is dependent on the materials used. Much experimentation continues to take place to determine which materials will produce light of what color.

LED Colors:

The first LEDs were only available in red. Yellow and Green LEDs came shortly after that, as

well as invisible infrared LEDs, like those used in TV remote controls. But it was a long time

before anyone could come up with a commercially viable blue LED.

The first blue LEDs were demonstrated in 1971 but they had too little light output to be of practical use. In August 1989, Cree introduced the first commercially available blue LED but it had very low efficiency, no more than about 0.03%. In 1993 high-brightness blue LEDs were demonstrated, with efficiencies reaching 10% but it wasn't until the late 1990s that blue LEDs became widely available. High-brightness blue LEDs revolutionized LED lighting, making high-power light sources practical.

| White LEDs: | Top |

There are actually 2 ways to make practical white light with LEDs, and both of them depend on blue LEDs. Once blue LEDs were developed, it became possible to put red, green, and blue LEDs next to each other, which the eye perceives as white. Some manufacturers even combined red, green, and blue LEDs into a single device. By controlling how much current each segment got, you could create virtually any color you want. But these devices have temperature stability issues, and since each color radiates in a slightly different pattern, the perceived color changes a bit as you move around. And although these devices are very flexible, they're also relatively complex, requiring sophisticated control circuits.

Another way of creating white light with LEDs is to coat the LED with a phosphor that absorbs the (monochromatic) light of the LED and re‑radiates it in a broad spectrum that we perceive as white. This is somewhat how fluorescent lighting works - the plasma inside the fluorescent tube actually produces (invisible) ultraviolet light. The phosphor coating on the inside of the tube absorbs the ultraviolet and then re‑radiates (fluoresces) it as visible light. It turns out that blue is one of the better colors to use for this method, so most white LEDs that you see are actually blue LEDs with a phosphor coating that makes them appear white. This seems like it would be inefficient, and some energy is lost in the conversion, but it's surprisingly efficient. More importantly, it's much easier (and therefore cheaper) to manufacture.

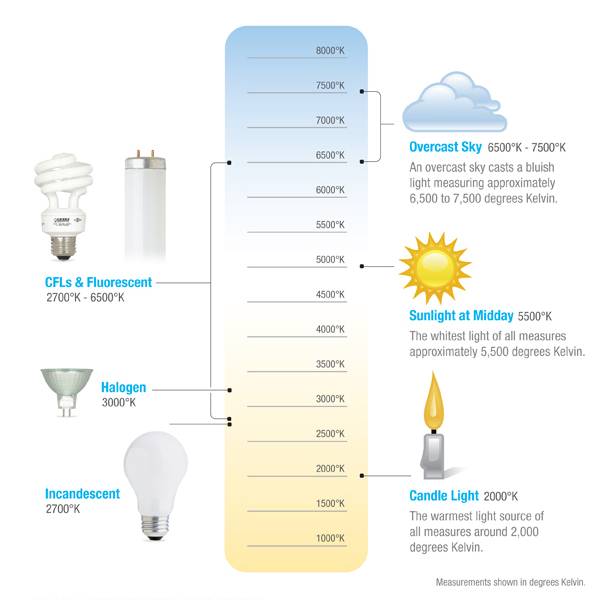

Light Color Temperature guide, courtesy of Lighting Matrix |

Correlated Color Temperature (CCT):

The color of different whites (warm, cool, etc) is usually described by the CCT - that is, the color

that a piece of tungsten or platinum would glow at if heated to that temperature, expressed in

degrees Kelvin (°K - centigrade scale, but based on the absolute zero of deep space). Sunlight

is about 5,000°K, while domestic incandescent lighting is closer to 3,000°K.

White LEDs can be bought in a range of "white" colors, from "cool" white to "warm" white. It's the phosphor coatings that allow LED manufacturers to fine tune the color. Warm‑white LEDs usually have a CCT of 2600‑3500°K and are typically used in residential applications like boat interiors. Cool‑white LEDs usually have a CCT of 6000‑6,500°K and are typically used in industrial or commercial applications. Cool‑white LEDs produce about 10% more light than warm‑white LEDs, so in situations where you need more light (like a masthead anchor light) then the cool‑white LEDs make more sense.

Current Limiting (Important):

LEDs don't take much voltage to turn on - typically about 1.5v and 5‑50 milliamps.

But applying more than that turn‑on voltage will cause the

current flowing through the LED to rise dramatically, usually burning out the LED. The current‑voltage

curve for LEDs is very non‑linear, and not at all like an incandescent bulb. Therefore, LED manufacturers

need to limit the current flowing through their LEDs. Early LEDs used a resistor to limit the

current, but this only works if your supply voltage is very constant. You might think that

your big 12v battery bank supplies a fairly constant 12 volts, but actually a battery's voltage

varies considerably, especially when the batteries are being charged.

It turns out to be very important that any 12v LEDs you buy not use resistor current limiting, but instead use a special integrated circuit (IC) to insure a constant current through the LEDs. We've found that some retailers will say that their LEDs use IC current limiting even when they don't. The way to be sure is to look at the input voltage specification. If the LEDs say they'll work from 11‑15 volts, stay away! They're only using resistor current limiting and they won't last. LEDs with IC current limiting should work with any voltage between 9‑30 volts.

Dimming LEDs:

LEDs can be dimmed either by reducing the current supplied or by pulsing the current to them and

varying the duty cycle (typically called Pulse Width Modulation, or PWM). Since most LEDs have

constant current devices built into the bulbs, varying the duty cycle is the preferred method.

Some dimmer circuits have a very low pulse frequency, because incandescents are slow to react and

work with this kind of dimmer, but LEDs react very quickly so if the pulse rate is less than about

200 Hz you'll notice the LEDs flickering. You want a dimmer with a pulse frequency high enough

that you don't see the flicker, but low enough that it doesn't interfere with your radio equipment.

Radio Frequency (RF) Interference:

Some of the IC current limiting chips being used in LEDs can produce RF interference that you can

hear in your SSB radio. Unfortunately, it's very difficult beforehand to tell if this will

happen, as vendors typically don't know. A reputable manufacturer will put a small capacitor

across the input leads to damp out any RF that's generated. If it bothers you enough, you can

add a small capacitor yourself. Of our 15 LED lighting circuits, we had 1 that caused some RF

interference, so we just turned those lights off when we wanted to use the radio. We actually

have several circuits that can cause RF interference (fridge, solar controller, computer power

supplies, etc) so turning off

one more isn't too onerous.

| LEDs and Moore's Law: | Top |

LED Light Output by Year - Note logarithmic scale on left (from Wikipedia) |

In 1965, Gordon Moore, co‑founder of Intel, wrote that the number of transistors that could be placed in an integrated circuit (IC) was doubling every 2 years. At the time, he predicted that this trend would continue for at least another 10 years. In fact, integrated circuit density (and therefore performance) has continued this amazing trend of doubling every 2 years from 1958 through today - for over half a century! Very few industries have experienced this magnitude of performance growth, and none for this long. (As an example of this sort of growth, if you start with a single penny and double it every day, you'll be a millionaire in less than a month.)

It turns out that LEDs are showing a very similar trend, partly because of IC growth. According to Wikipedia, "The development of LED technology has caused their efficiency and light output to rise exponentially, with a doubling occurring about every 36 months since the 1960s, in a way similar to Moore's law." So expect LEDs to get more efficient and to produce more light (and probably to get cheaper as well). We should say that the information presented in this article was accurate as of early 2012, but the industry is obviously moving quickly.

Light Output:

With incandescent lights, folks talk about light output in terms of Watts (a 60W bulb, for

instance). This

is really silly, as Watts are a measure of heat, not light. Most folks don't even know that

the "long life" bulbs get their long life by not putting out as much light as the same wattage

normal bulb. Even fluorescent bulbs are rated in Watts, despite their generating their light

in a completely different way than incandescent bulbs.

Power consumption (Watts) is certainly important in comparing LEDs, but more important is their light output, which is usually expressed in Lumens (lm). Since we want to compare apples to apples, we need a conversion figure of some sort. Our very rough observations say that a 10W halogen G4 bulb puts out about 100 lumens of light. We've also noticed that each Surface Mount (SMD) 5050 LED chip puts out about 12 lumens. So a G4 replacement with 12 SMD5050 chips puts out about 140‑150 lumens, significantly more than the 10W halogen bulb it replaces (but not as much as a 20W halogen). You can see this pretty easily if you put the lit bulbs side by side. And our masthead light, with 40 SMD5050 chips, is putting out almost 500 lumens, way more than the 10W incandescent it replaced (we usually have the brightest anchor light in an anchorage).

Using LEDs for a Masthead Tri-Color Light:

Most masthead tri‑color bulbs draw 25W or 2A, so running one all night burns up 25 amp‑hours (Ah) of

electricity. That's a sizeable chunk out of an energy budget, so replacing your tri‑color

bulb with a more efficient LED sounds like a good idea. But there are problems...

Typical LED Masthead light using 49 SMD5050 LEDs |

A bulb for a masthead tri‑color fitting has a special vertical filament. This is so an observer will see your light through your red lens or your green lens, but not both. The switch between red and green as they move across your bow should be almost instantaneous. But an LED array is not a thin vertical line. It's a relatively fat blob of light. If you put an LED "bulb" in a tri‑color fitting, an observer directly in front of you will see light coming through both the red and the green segments at the same time. Their eye will combine these colors and they'll perceive it as bright yellow, unless you've opted for a bluer cool‑white LED, in which case they'll perceive it as white. That means that, for a narrow segment directly in front of you, an observer will think you're going away from them instead of coming towards them! This is definitely not what you want.

One option we've seen is to use a powerful vertically mounted LED shining into a conical mirror. The mirror will reflect the light into a circle around your boat, and the single LED is near enough to a point‑source of light to avoid the problems of a fat bulb. These types of bulbs are available (for ~$80) but we have yet to see one with sufficient light output. The light has to be very bright (at least 300 lumens) to be seen at a couple of miles after going through the red and green plastic lenses.

Another possible solution is to dispense with the red and green plastic lenses and just go with a clear lens and a "bulb" with red, green, and white LED segments. This might work if the LEDs were small enough and there was a baffle (wall) between the different colors of LED. These sorts of LEDs are also available (and expensive) but the all‑around clear lenses are less easy to find, unless you want to stack 2 anchor‑light fittings on top of each other.

If anyone has a better solution, we'd love to hear about it.

| Luminous Efficiency (light output vs. watts consumed): | Top |

We think that our 10W halogen G4 bulbs produce about 100 lumens of light, so their luminous efficiency is about 100/10=10 lumens/Watt (lm/W). A typical 60‑100W domestic incandescent bulb usually produces about 15 lm/W. Compact fluorescents are much better, coming in around 100 lm/W. We haven't measured our LED G4 replacements accurately, but we believe they're producing about 150 lumens and consuming about 1.3W, so they're actually a bit better than compact fluorescents. In the lab, LEDs have been measured well in excess of 200 lm/W, and as the curve above shows, they're quickly getting more efficient.

| What we use on Ocelot: | Top |

Ocelot's lighting was originally quite a mixture. We had:

26 G4 halogen bulbs as area lighting (mostly 10W but some 5W and two 20W bulbs in the cockpit) 13 incandescent reading lights with a bayonet base and 2 contacts on the bottom 8 "festoon" bulbs in the heads with contacts at each end of a cylindrical tube 16 tiny engine instrument lights, and 5 navigation lights in various configurations

In 2006 we started experimenting with LED lighting by replacing our masthead anchor light with an LED bulb from LED Shop Online in Queensland, Australia (then $40). It was wonderfully bright initially but within a year it was noticeably dimmer. Several segments had burned out so we asked the supplier if they would replace it. Somewhat surprisingly, they did. They promised that the new bulb would last longer, but it also soon died. Since our battery voltage never gets above 14.1v, we were quite disappointed. Presumably these masthead lights only used resistor current limiting, despite claims to the contrary.

SMD5050 G4 LED replacement |

In 2010 we started looking into replacing our interior G4 halogen bulbs with LEDs, starting with expensive ($11) samples from the USA. Then we found a factory in Hong Kong with better G4 replacements for only $4. We found that the surface mount (SMD) 5050 LED chips did a good job, and they could be bought in a pleasant Warm White color. These G4 replacements are actually a small printed circuit disk with LED segments on one side and some electronics on the other. The pins to plug the disk in can come out of the side or out of the back, depending on what sort of fitting you have.

After dealing with a few different companies, we've now settled on Lighting Matrix, an LED factory in Hong Kong. What we like most about them is their dedication to quality. For instance, ALL of their LEDs come with IC current limiting (this was an extra cost option at most of the other places we talked to). They're mostly into domestic lighting, of course, but they have several types of G4 replacements (under Other Lights, GL Series) as well as other 12vDC lights. Their Flexible Strip Lights can be bought by the meter and cut to wherever length you want, and they work very well as cove or decorative lighting. We've found that Rigid Strip Lights work well in our cockpit when we want lots of light.

Since they can put just about any base on whatever lights you want, things can get complex enough that you have to order through their sales team. We've found that Bill Deng is very responsive and really tries hard to accommodate whatever strange needs you might have. But remember that Lighting Matrix is a factory, not a retailer, so they don't like small numbers of parts. They'll sometimes deal with us small guys, but they have no stock on hand, so it will take them a few days to make up your order before they can ship it to you. Also, shipping costs from Hong Kong make it advisable to order stuff all at once, since DHL has a minimum price and LEDs don't weigh very much.

Equipment Pages:

Cruising Info:

Top Level: Home | Destinations | Cruising Info | Underwater | Boat Guests | Ocelot | Sue | Jon | Amanda | Chris | Site Map | Make a Comment

|

If our information is useful, you can help by making a donation |

Copyright © 2000‑ Contact: Jon and Sue Hacking -- HackingFamily.com, svOcelot.com. All rights reserved.